CTD and Rosette Setup¶

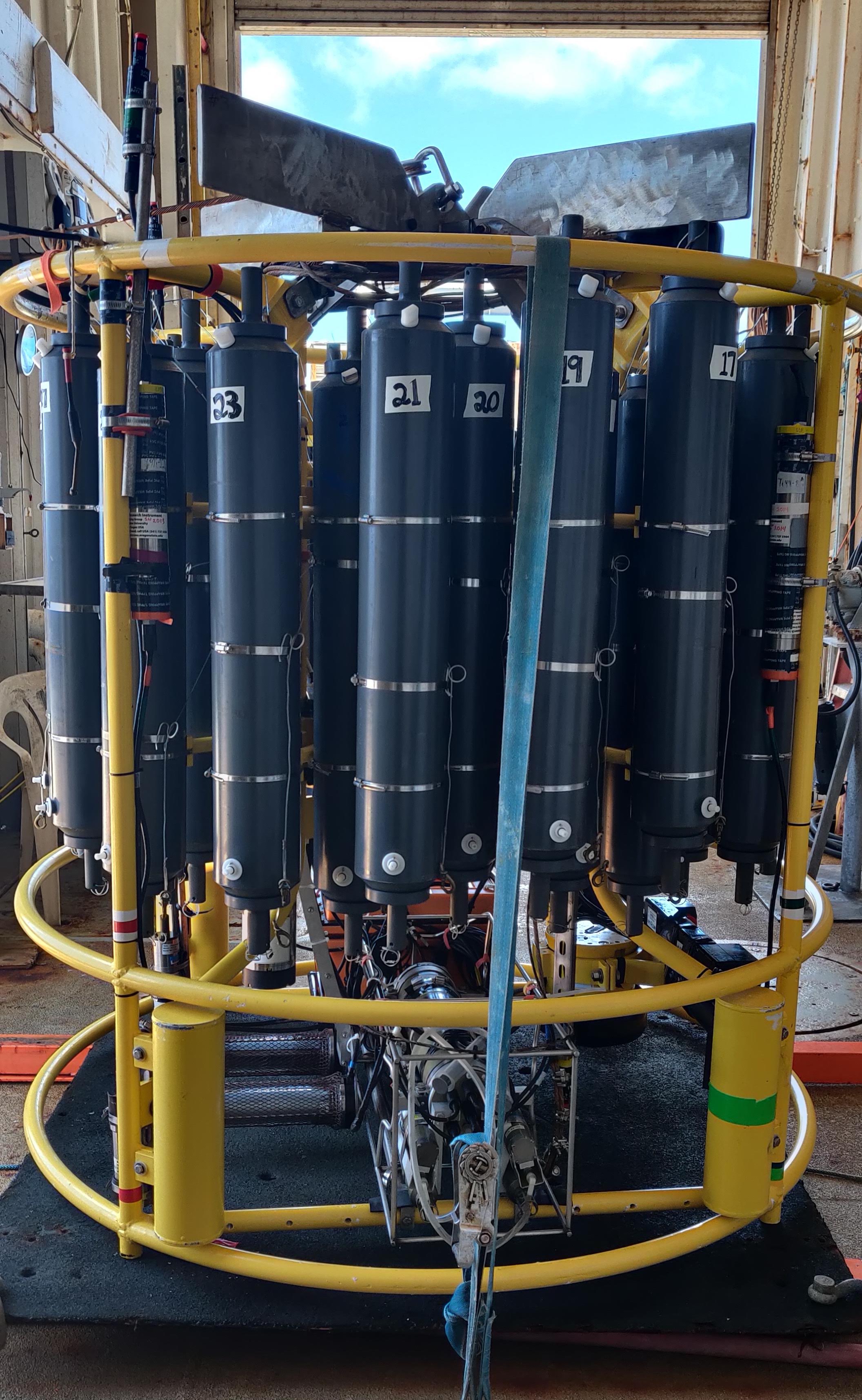

For P02E-2022 a SIO STS 36-place yellow rosette and bottles were used. The rosette was sent to Guam in early January, 2022 for P02W. The rosette and bottles were built before P06 2017, making this the fourteenth time this package has been deployed. A steel bridle was added to the top of the rosette to adapt to the winch head. The bottles were made with new PVC, with new non-baked o-rings and electro-polished steel springs. Springs within the Bullister-style Niskin bottles were electropolished stainless steel. Bottle lanyards were made from 300-pound monofilament. No sample contamination has been noticed by the change in o-rings and springs. The package used on P02E-2022 weighs roughly 1500 lbs in air without water and 2350 lbs in air with water. The package used on P02E-2022 weighs roughly 950 lbs in water. In addition to the standard CTDO package on GO-SHIP cruises three chipods, two LADCP, and one UVP were mounted on the rosette.

During the cruise we encountered a handful of problems, most notably noise between the primary and secondary CTD lines. We describe all of the above in more detail in the sections below.

Underwater Sampling Package¶

CTDO/rosette/LADCP/UVP/chipod casts were performed with a package consisting of a 36 bottle rosette frame, a 36-place carousel and 36 Bullister style Niskin bottles with an absolute volume of 10.6 L. Underwater electronic components primarily consisted of a SeaBird Electronics housing unit with Paroscientific pressure sensor with dual plumbed lines where each line has a pump, temperature sensor, conductivity sensor, and exhaust line. A SeaBird Electronics membrane oxygen sensor was mounted on the “primary” line. A reference thermometer, RINKO oxygen optode, transmissometer, chlorophyll-a fluorometer, and altimeter were also mounted on the rosette. Chipod, LADCP, and UVP instruments were deployed with the CTD/rosette package and their use is outlined in sections of this document specific to their titled analysis.

CTD and cage were horizontally mounted at the bottom of the rosette frame, located below the carousel for all stations. The temperature, conductivity, dissolved oxygen, respective pumps and exhaust tubing was mounted to the CTD and cage housing as recommended by SBE. The reference temperature sensor was mounted between the primary and secondary temperature sensors at the same level as the intakes for the pumped temperature sensors. The transmissometer was mounted horizontally on the lower LADCP brace with hose clamps, avoiding shiny metal inside that would introduce noise in the signal. The hose clamps for the transmissometer were covered in black electrical tape. The oxygen optode, fluorometer, and altimeter were mounted vertically inside the bottom ring of the rosette frames, with nothing obstructing their line of sight. One 300 KHz bi-directional Broadband LADCP (RDI) unit was mounted vertically on the bottom side of the frame. Another 300 KHz bi-directional Broadband LADCP (RDI) unit was mounted vertically on the top side of the frame. The LADCP battery pack was also mounted on the bottom of the frame. The LADCP and LADCP battery pack were mounted near (90°) each other at the beginning of the cruise. Imagining the bow of the ship to be north, the LADCP battery was mounted on the south side of the rosette, the up/down LADCPs were on the west side, the UVP on the east, and CTD mounted to the north (Figure 1).

Equipment |

Model |

S/N |

Cal Date |

Stations |

Group |

|---|---|---|---|---|---|

Rosette |

36-place |

Yellow |

– |

118-205 |

|

CTD |

SBE9+ |

1281 |

– |

118-205 |

|

Pressure Sensor |

Digiquartz |

136428 |

Dec 7, 2021 |

118-205 |

|

Primary Temperature |

SBE3+ |

36049 |

Mar 17, 2022 |

118-205 |

|

Primary Conductivity |

SBE4C |

43578 |

Mar 22, 2022 |

118-205 |

|

Primary Pump |

SBE5 |

51892 |

– |

118-196 |

|

Primary Pump |

SBE5 |

51781 |

– |

197-205 |

|

Secondary Temperature |

SBE3+ |

34138 |

Mar 17, 2022 |

118-205 |

|

Secondary Conductivity |

SBE4C |

42569 |

Mar 17, 2022 |

118-205 |

|

Secondary Pump |

SBE5 |

53626 |

– |

118-205 |

|

Transmissometer |

Cstar |

1873DR |

Jan 5, 2022 |

118-205 |

|

Fluorometer Chlorophyll |

WetLabs ECO-FL-RTD |

4334 |

– |

118-205 |

|

Dissolved Oxygen |

SBE43 |

431508 |

Oct 8, 2021 |

118-205 |

|

Oxygen Optode |

JFE Advantech Rinko-III |

0251 |

Apr 7, 2017 |

118-205 |

|

Reference Temperature |

SBE35 |

0105 |

Mar 15, 2022 |

118-205 |

|

Carousel |

SBE32 |

1178 |

– |

118-205 |

|

Altimeter |

Valeport 500 |

53821 |

– |

118-205 |

|

UVP |

– |

201 |

– |

118-205 |

|

LADCP (uplooker) |

WHM300kHZ |

12734 |

118-205 |

||

LADCP (downlooker) |

WHM300kHZ |

3441 |

118-205 |

||

LADCP (downlooker) |

WHM300kHZ |

24477 |

186-191(*) |

||

Chipods |

Chipod |

2014 Ti44-8 |

– |

118-162 |

|

Chipods |

Chipod |

2013 TI44-12 |

– |

118-162 |

|

Chipods |

Chipod |

2032 Ti44-15 |

– |

118-162 |

|

Chipods |

Chipod |

2025 Ti44-7 |

– |

163-205 |

|

Chipods |

Chipod |

2017 TI44-6 |

– |

163-205 |

|

Chipods |

Chipod |

2027 Ti44-? |

– |

163-205 |

Package sensor setup from south (for all rosette figures, orientation is defined as north being toward the bow).¶

Package sensor setup from east.¶

Package sensor setup from north.¶

Package setup from southwest, from left to right: CTD cage, downward facing chipod, downward facing LADCP, transmissometer bar.¶

Package setup from southwest, from left to right: (Foreground) ECO fluorometer, UVP, RINKO, altimeter.¶

Package setup from west.¶

Package setup from west, top view.¶

Winch and Deployment¶

The CAST6 winch and deployment system was used for the two test stations and the first core station. After a hydraulic oil leak was found, the rosette was switched to the DESH5 winch for remaining stations. The rosette system was suspended from a UNOLS-standard three-conductor 0.322” electro-mechanical sea cable. The sea cable was terminated with an Evergrip (primary), Guy Grip (secondary), and set of Crosby Clips (tertiary). No electrical issues occurred on P02E.

The deck watch prepared the rosette 10-30 minutes prior to each cast. The bottles were cocked and all valves, vents, and lanyards were checked for proper orientation. Any biofouling noted was cleaned off the outside of the rosette before the next cast, and the inside of the bottles were checked for biofouling and sprayed down. The LADCP technician would check for LADCP battery charge, prepare instrument for data acquisition, and disconnect cables. The LADCP technician also dealt with the UVP, disconnecting cables at the same time. Once stopped on station, the Marine Technician would check the sea state prior to cast and decide if conditions were acceptable for deployment. The rosette was moved from the sampling bay out to the deck using the Revelle’s tugger-driven cart while using the CAST6. Following the switch to the DESH5, the rosette was moved from the sampling bay using a pallet jack. Once on deck, sea cable slack was pulled up by the winch operator. CTD watch standers would then turn on the deckbox and begin data acquistion, and the cast would begin. For casts performed with the DESH5, members of the science party used taglines to assist with deployment and recovery. Recovering the package at the end of the deployment was the reverse of launching. Once rolled back into the sampling bay, a technician secured the cart to the deck using additional ratchet straps. The carousel was rinsed and sensors were cleaned (as described below) after every cast, and then samplers were allowed to begin collecting water.

Maintenance and Calibrations¶

During P02E-2022 routine maintenance was done to the rosette to ensure quality of the science done. Actions taken included rinsing all electrical instruments on the rosette down with fresh water after each cast and adjusting hose clamps and guide rings as needed such that lanyards had appropriate tension. Care was taken not to rinse the spigots and other parts of the bottle that might be touched by samplers in order to not contaminate the samples. After each cast, syringes of fresh water were connected to the plumbed lines to rinse the sensors and allow them to soak between casts. The rosette was routinely examined for valve and o-ring leaks, which were maintained as needed. SBE35RT temperature data was routinely downloaded each day.

Every 20 stations, the transmissometer windows were cleaned and on deck blocked and un-blocked voltage readings were recorded prior to the cast. The transmissometer was also calibrated before the start and after the end of science operations.

“Dark” bio casts were performed periodically, where the fluorometer sensor face was covered with black electrical tape. Dark casts allowed for background noise to be measured as function of depth, since the fluorometer would not measure any signal.

Logs¶

In port: Preparation of the CTD and rosette was minimal as it had the same setup as P02W 2022, which had just been completed. Integrity checks on the rosette, such as checking lanyard angles, o-ring and lanyard replacement, and spigot movement were performed during fueling before transit to test station. We are using a new mounting system for the downward looking LADCP which has the LADCP clamped facing inward instead of outward, which will cause problems if we need to change that LADCP in rough weather.

June 14, 2022

90101 - Test bio cast to 1000 m. While cocking bottles, #19 top inner-lanyard came untied and suddenly released the spring tension. Deferred fixing lanyard until during transit to first station to save time.

90102 - Test core cast to 1000 m. No issues of note besides missing bottle #19.

June 16, 2022

11801 - Bottle #19 leaking from bottom o-ring; replacement inner-lanyard likely too long causing spring to be under-tensioned. CAST6 hydro boom found to be leaking hydraulic fluid after cast; swapping rosette to DESH5, which will require taglines for deployment and recovery, manual winch payout, and sampling out on deck instead of the hangar.

11901 - Bio cast aborted at 40 m due to modulo errors and RS-232 comms failure. Termination is bad and water was intruding under pressure; cut off 10 m of cable and there was water inside. Before next cast, deck was scrubbed with Simple Green to remove oil slick. Sensors were capped, bottles were closed, and rosette cover put on before scrubbing.

11902 - Bio cast aborted again at 40 m due to RS-232 comms failure. Cut off 100 m of cable and conductor wires had much less corrosion. Reterminated and attempting another cast.

11903 - Bio cast successful to 1000 m and back.

11904 - Bottle #34 outer lanyard broke from abrasion. Bottle #19 inner-lanyard swapped after cast.

June 17, 2022

12001 - Bottle #17 top knot came untied and released spring tension (same as 90101 bottle #19) during prep; cast performed with capless bottle #17. Bottle #19 leaking again upon recovery; swapped in a new Niskin bottle.

12101 - Swapped in new Niskin bottles for #17 and #19 before cast. Rosette came back to surface missing bottle #30. Bottle #17 leaking from bottom on recovery after opening air vent; outer lanyard may be too tight and preventing bottle from staying well sealed.

12201 - Bottle #19 swapped out and bottle #30 replaced, both are spares from Revelle’s stockpile. Bio cast + float

12202 - Bottle #5 closed on ADCP cable and did not seal; was not sampled. Bottle #19 has low temp, likely closed early. Adjusted bottle downward before deployment such that it had sufficient tension when cocked without being overtensioned after being fired.

June 18, 2022

12301 - Bottle #19 draw temperature a little low; lanyard was a little loose and likely closed itself during downcast. Tightened up before next cast.

12401 - Bottle #11 did not fire, trigger is sticky.

12501 - Dark bio cast; fluorometer was not fully taped over and still had some response.

June 19, 2022

12502 - No issues noted.

12601 - Chipod #12 was flooded, swapped with #11. Bottle #10 lanyard was routed around neighboring standoff and bottom cap was stuck open; no water at all in bottle.

12701 - Lowered bottle #6 before cast, top handle was bumping into frame.

12801 - Bio cast; No issues noted.

12802 - No issues noted.

June 20, 2022

12901 - Bottle #30 had small leak; top bottle mating surface has a gouge in it, swapping in the original bottle #17. Replaced spigot on bottle #12.

13001 - No issues noted.

13101 - Bio cast; No issues noted.

13102 - Bottle #33 did not fire. Bottles #15 and 16 had vent caps left open. Bottle #28 CFC syringe broke so will not have a sample

June 21, 2022

13201 - No issues noted.

13301 - Bottle #2 exceptionally warm; check other params.

13401 - Bio cast; No issues noted.

13402 - Bottle top caps hit with hook during recovery. Oxygen data makes it appear to be #18 and 19.

June 22, 2022

13501 - No issues noted.

13601 - Altimeter a little spiky at bottom, could be ground composition causing bad returns.

13701 - Bio cast; No issues noted.

13702 - 1 modulo error around ~5700 m. Mistripped 8 bottles (27-34) at same depth, keyboard/user error.

13703 - Re-cast to 350 m. Bottle #10 bottom cap was left uncocked, flag bad.

June 23, 2022

13801 - Lowered bottles #17 and 19 before cast to prevent issue of hitting bottle tops with gaffing hooks.

13901 - Change out top o-rings and air vents on bottle #4 and 28 before cast.

14001 - Bio cast; No issues noted.

14002 - Bottle #17 top inner-cap lanyard broken at depth, came back missing spring.

June 24, 2022

14101 - No issues noted.

14201 - No issues noted.

14301 - Bio cast; No issues noted.

14302 - Outer lanyards on bottles #34 and 35 changed before due to visible chafing.

June 25, 2022

14401 - Noisy T/C residuals during soak, likely due to prop wash and/or the soak being very near the thermocline.

14501 - New spigot on bottle #1. Swapped clear monofilament on top cap of bottle #17 for newer, blue mono. New inner-cap lanyards on bottles #11, 22, and 32 due to slightly abrasion. Zeroes in SBE3+ primary are back

14601 - Bio cast; No issues noted.

14602 - Bottle #33 did not fire. Salinity bottle #9 from box B was chipped and replace after cast.

June 26, 2022

14701 - No issues noted.

14801 - Swap cables on T1 and T2 to see if zero frequency issue follows cable. Zeroes stayed on same sensor (T1), issue believed to be the SBE9+ (CTD).

14901 - Bio cast; No issues noted.

14902 - No issues noted.

15001 - No issues noted.

June 27, 2022

15101 - No issues noted.

15201 - Bio cast; No issues noted.

15202 - No issues noted.

15301 - No issues noted.

June 28, 2022

15401 - Bottle #14 leaking again, Gabe says PVC weld failing. Swapping in one from backup rosette.

15501 - Bio cast; No issues noted.

15502 - No issues noted.

15601 - Rusty spring found in bottle #14, replaced after cast.

15701 - RS-232 comms timeout error mid-cast @ 3870m

June 29, 2022

15801 - No issues noted.

15802 - No issues noted.

15901 - Bottle #6 leaking

16001 - Bottle #6 leaking again, changed bottom o-ring.

June 30, 2022

16101 - No issues noted.

16102 - Bottle #6 leaking, velcro stuck in cap.

16201 - No issues noted.

16301 - Swapped all chipod pressure cases before cast. Taglines wrapped around spigots during deployment.

16401 - Dark bio cast. CFCs sampled bottle #25 but syringe was left open and leaked.

July 1, 2022

16402 - RS-232 comms timeout error at 1650m, data acquisition was not interrupted.

16501 - Changed o-ring on bottle #19. O2 resampled bottle #31

16601 - Bottle #4 leaking; swap air vent and top cap o-rings.

16701 - No issues noted.

16702 - No issues noted.

July 2, 2022

16801 - No issues noted.

16901 - No issues noted.

17001 - Bio float; No issues noted.

17002 - No issues noted.

July 3, 2022

17101 - No issues noted.

17201 - Adjusted guide rings on bottles 2 and 22 to tighten up bottom handles.

17301 - Bio cast; No issues noted.

17302 - SeaSave stopped responding during bottle stop; mouse still working; fixed itself after 30s or so.

17401 - RS-232 comms timeout error at 750m

July 4, 2022

17501 - No issues noted.

17601 - Bio cast + sampling for “planktoscope”

17602 - No issues noted.

17701 - No issues noted.

17801 - No issues noted.

July 5, 2022

17901 - Bio cast; No issues noted.

17902 - No issues noted.

18001 - Salts sampled by multiple people, bottles in box out of order.

18101 - No issues noted.

18201 - Bio cast; No issues noted.

July 6, 2022

18202 - No issues noted.

18301 - Ship lost power during 20m soak; aborted and recovered.

18302 - No issues noted.

18401 - No issues noted.

18501 - Bio cast; No issues noted.

July 7, 2022

18601 - No issues noted.

18701 - No issues noted.

18801 - Bio cast; No issues noted.

July 8, 2022

18802 - No issues noted.

18901 - No issues noted.

19001 - No issues noted.

19101 - Bio cast, float; No issues noted.

July 9, 2022

19102 - No issues noted.

19201 - No issues noted.

19301 - Primary T/C/O extremely spiky at 300m on upcast, most likely clogged. Upon recovery, primary plumbing was opaque with biofouling. Tubes removed and cleaned; re-assembled plumbing and cleaned sensor line with with 1% Triton-X, flush with fresh water. Secondary line plumbing was loose from C to pump, slid pump forward to close gap.

July 10, 2022

19401 - Test cast to 100m to make sure plumbing is okay.

19402 - Bio cast; No issues noted.

19403 - Aborted, UVP shunt not removed

19404 - No issues noted.

19501 - No issues noted.

19601 - Primary pump problems again near bottom, no bio-fouling upon recovery. Top o-ring on impeller was broken with 1/3 fully missing; swapped in 05-1781.

19701 - Test cast to 100m to check new pump. Primary/secondary residuals still poor over full cast.

19702 - Swapped y-cable and rotated pump to have exhaust at 45º angle. Deck to ensure pump flow, looks fine. Test cast turned bio cast.

19703 - No issues noted.

July 11, 2022

19801 - Salt bottle #5 from box S dropped during sampling and broken; replaced with spare.

19901 - No issues noted.

20001 - Bio cast; No issues noted.

20002 - No issues noted.

July 12, 2022

20101 - RS-232 comms failure on upcast at ~400m, modulo error and overflow light on deckbox. Power cycled deckbox, restarted acquisition in 20101_2 file without issue for remainder of cast.

20201 - No issues noted.

20301 - Bio cast; No issues noted.

20302 - Bottle #3 bottom cap found unclipped during recovery, likely uncocked during deployment.

20401 - No issues noted.

July 13, 2022

19103 - Dark bio cast; No issues noted.

19104 - No issues noted.

19002 - No issues noted.

July 14, 2022

18902 - Salt bottle #33 from box S broken during sampling.

18803 - Bio cast; No issues noted.

18804 - No issues noted.

18702 - No issues noted.

18602 - No issues noted.

Sensor Problems¶

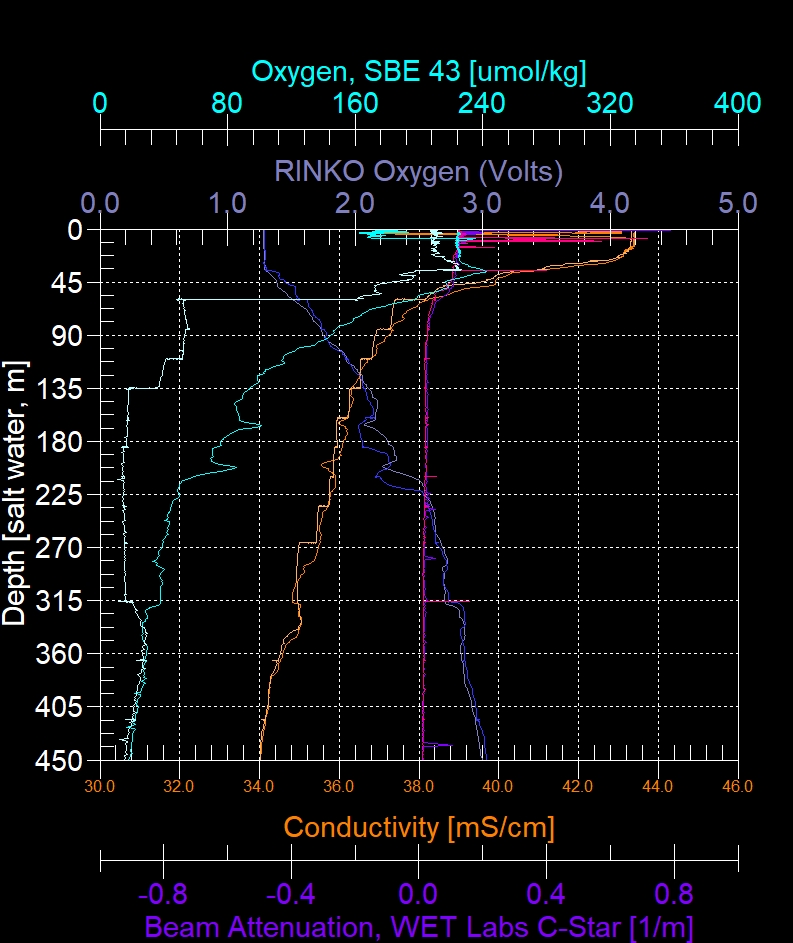

Biofouling: The SBE5 pump on the primary T/C/O line showed signs of bad flow starting during the upcast on 19301 (Fig. 1). Upon recovery, plumbing tubes were opaque with biofouling. Plumbing was disassembled and cleaned with 1% Triton-X. The lines were then re-attached to the T/C/O sensors and the entire line was flushed with the same 1% Triton-X and then flushed with fresh water.

Biofouling/clog evident at 315m due to oxygen decrease and staying constant during upcast.¶

Pump problems: The primary pump became an issue again on cast 19601 with what appeared to possibly be another clog. Upon recovery, no biofouling was found so the pump was removed and inspected. The top o-ring on the impeller was broken and assumed to be the cause. Pump 5-1781 was swapped in and deployed for a test cast. T/C residuals between primary and secondary line were erratic during test cast to 100m. Rosette was recovered and the pump exhaust was re-oriented to 45º and the y-cable was swapped. Deck test and test cast ensured pump was now working fine.